Valve Coating Service

Restore performance, extend service life, and protect critical flow control assets against severe corrosion and erosion.

Valves are the most critical control points in any fluid-handling system and are constantly exposed to the harshest operating conditions—turbulence, cavitation, erosion, abrasion, and chemical attack. At Kirloskar Corrocoat Private Limited (KCPL), we offer specialized Valve Refurbishment and High-performance Glass Flake Coating Solutions for both new and old valves, engineered to enhance durability, reliability, and efficiency.

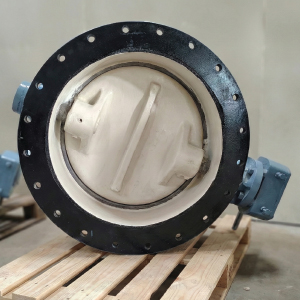

Valve Refurbishment & Glass flake Coating:

For valves already in service and showing signs of wear, corrosion, erosion, or leakage, KCPL offers a complete refurbishment solution combined with high-performance glass-flake coating systems.

Our integrated solution combines:

- Precision mechanical repair & rebuilding

- Reverse engineering and profile restoration

- High-performance Kirloskar Corrocoat glass-flake coating systems

This process significantly extends valve life, reduces replacement costs, minimizes downtime, and restores optimal flow efficiency. Refurbishment provides a highly economical alternative to purchasing new valves, while delivering superior protection and service life.

New Valve with High-performace Glass flake coating

New industrial valves—whether for water, seawater, chemicals, effluents, slurry, or high-salinity service—benefit massively from high-performance protective coatings.

Benefits:

- Prevent corrosion before it starts

- Improve internal fluid efficiency with smoother surfaces

- Protect against abrasion, erosion, and chemical attack

- Increase operational life 2–4× compared to uncoated OEM valves

- Reduce early-stage failures and maintenance interventions

Parts to be coated are Internal bodies, discs, gates and external surfaces depending on the environment and service conditions.

Typical applications include:-

- Butterfly valves (CW, wafer, lug, double-flanged)

- Gate valves

- Globe valves

- Check / NRV valves

- Ball and plug valves

- Diaphragm valves

- Knife gate valves

- Customized industrial valves

© 2023 KIRLOSKAR CORROCOAT PRIVATE LIMITED. ALL RIGHTS RESERVED | CIN NO. U28920PN2006PTC022240