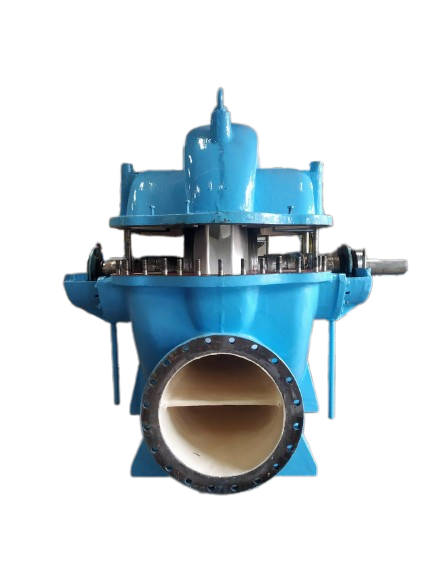

Pump Refurbishment and Efficiency Improvement Coating

Kirloskar Corrocoat Private Limited offers a range of pump services both on site via a dedicated professional team, or at our Kirloskarvadi workshop. Our workshop houses a number of facilities which include machining, balancing, reverse engineering, corrosion engineering & has Asia's Largest Pump Testing Facility.

ENERGY IMPROVEMENT COATINGS:

Increased concern relating to the more effective use of energy resources has resulted in the introduction of new technology in coating materials. This is aimed at maximising the performance of pumping systems used in areas including power generation, refineries etc cooling water systems, the process industries and water and waste treatment.

Coating specialists Corrocoat were pioneers in this field of research. The Fluiglide system – first introduced in 1985 – has now been applied to literally Lakhs of pumps worldwide, achieving in every case significant improvements in efficiency. The performance of the process has been the subject of extensive test procedures, including evaluation by major manufacturers, utilities and industrial users. Fluiglide materials offer dual benefits. The system not only achieves notable increases in overall efficiency levels, but also provides an effective corrosion barrier, preventing early fall-off in performance due to nodular growth and surface corrosion.

REFURBISHMENT TECHNOLOGY

Refurbishment intends to restore the component to original or desired level within allowable tolerance frame resulting in defined output parameters which should work for longer period of time. The refurbishment treatment will vary from component to component and will depend upon the present change with respect to desired dimensions. Reinforcing material will vary accordingly for each case. With the use of the reinforcing material, holes developed in the components can be plugged or filled up to original or desired level. These reinforcements also make it possible to recreate broken and missing portions of the component or modify the shape of the component. This ability gives the distinct advantage of suitably altering the performance of the equipment itself which many times is required in case of pumping equipment’s due to changes in operating conditions which necessitate change in nature of pump characteristics and operating point.

Kirloskar Corrocoat offers a range of pump services both on site via a dedicated professional team, or at our workshop. Our workshop houses a number of facilities which include machining, balancing, reverse engineering and corrosion engineering.

- Site removal and transportation

- Full strip down reports, if requested

- Machining facilities

- Hydrostatic test facilities

- Reverse engineering of parts

- Replacement of components

- Shaft reclamation and in-house dynamic balancing of rotating components

- Re-installation if requested

- Design modification work undertaken to improve equipment manufacture and upgrade to meet customers’ latest requirements

- Corrosion protection coating application

- Dynamic Balancing

© 2023 KIRLOSKAR CORROCOAT PRIVATE LIMITED. ALL RIGHTS RESERVED | CIN NO. U28920PN2006PTC022240