Efficiency Improvement of Pump by Coating

At Kirloskar Corrocoat Private Limited, we specialize in providing cutting-edge coating solutions designed to enhance the efficiency and performance of pumps across various industries. Our pump efficiency improvement coating services are meticulously crafted to meet the unique needs of our clients, helping them achieve higher productivity, reduce energy consumption, and extend equipment lifespan.

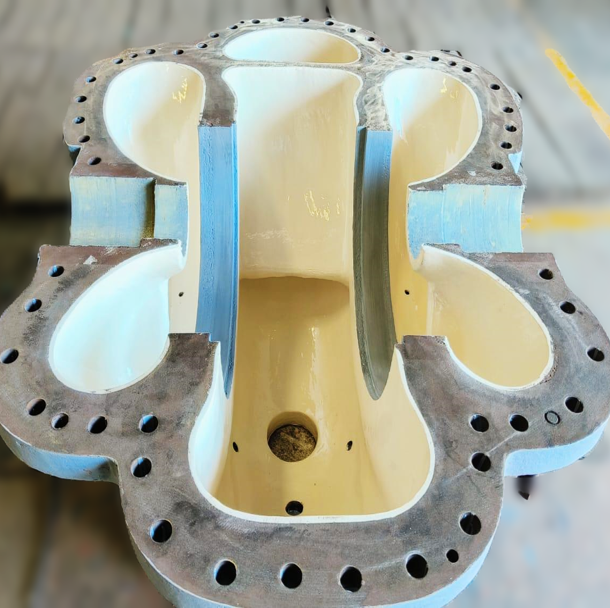

Pump Running Costs – A Perspective View:

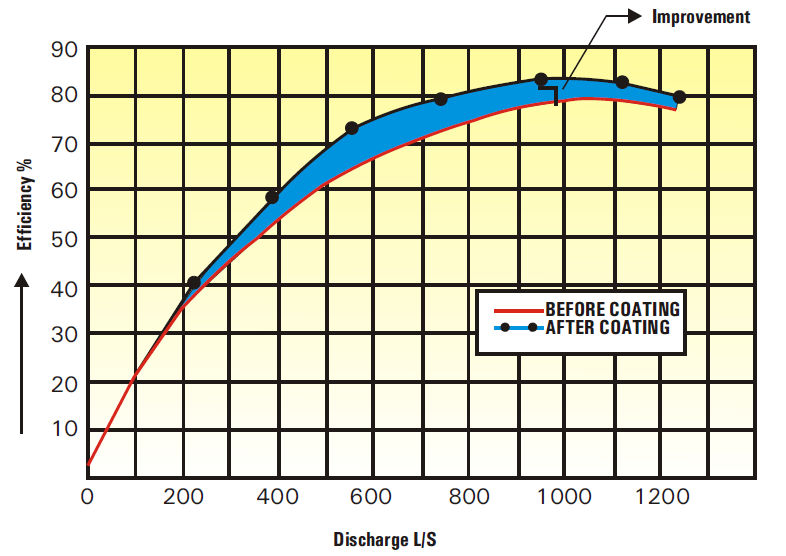

For a pump with a lifetime expectancy of 20 years (for example), only 2.5-3% of the cost of pump operation relates to the purchase price of equipment. A further 2-2.5% is attributable to maintenance costs. The remaining 95% is consumed in the cost of the power to run the unit. With the ever increasing cost of energy over the life of a pump running continuously, the potential savings from the average 4-5% improvement offered by the Fluiglide system offers a fast payback on the initial coating costs.

We ensure peak performance of your Pumping system:

We provide Energy improvement coatings to improve the Pump efficiency over and above already achieved thereby giving substantial saving in energy costs. These coatings have potable water certification. By use of these coatings, the efficiency of the new Pumps can be improved from 1% to 3% depending on the type of Pump and specific speed. Our experience & expertise offers the best Pump refurbishment solutions in case of old used Pumps, where the efficiency improvement is more than 4% depending on the type of Pump, specific speed, and pump condition. The ROI on these coatings due to energy savings is less than 6 months.

We convert your expenditures in-to INVESTMENTS:

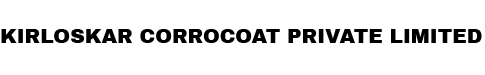

The coating System:

Fluiglide:

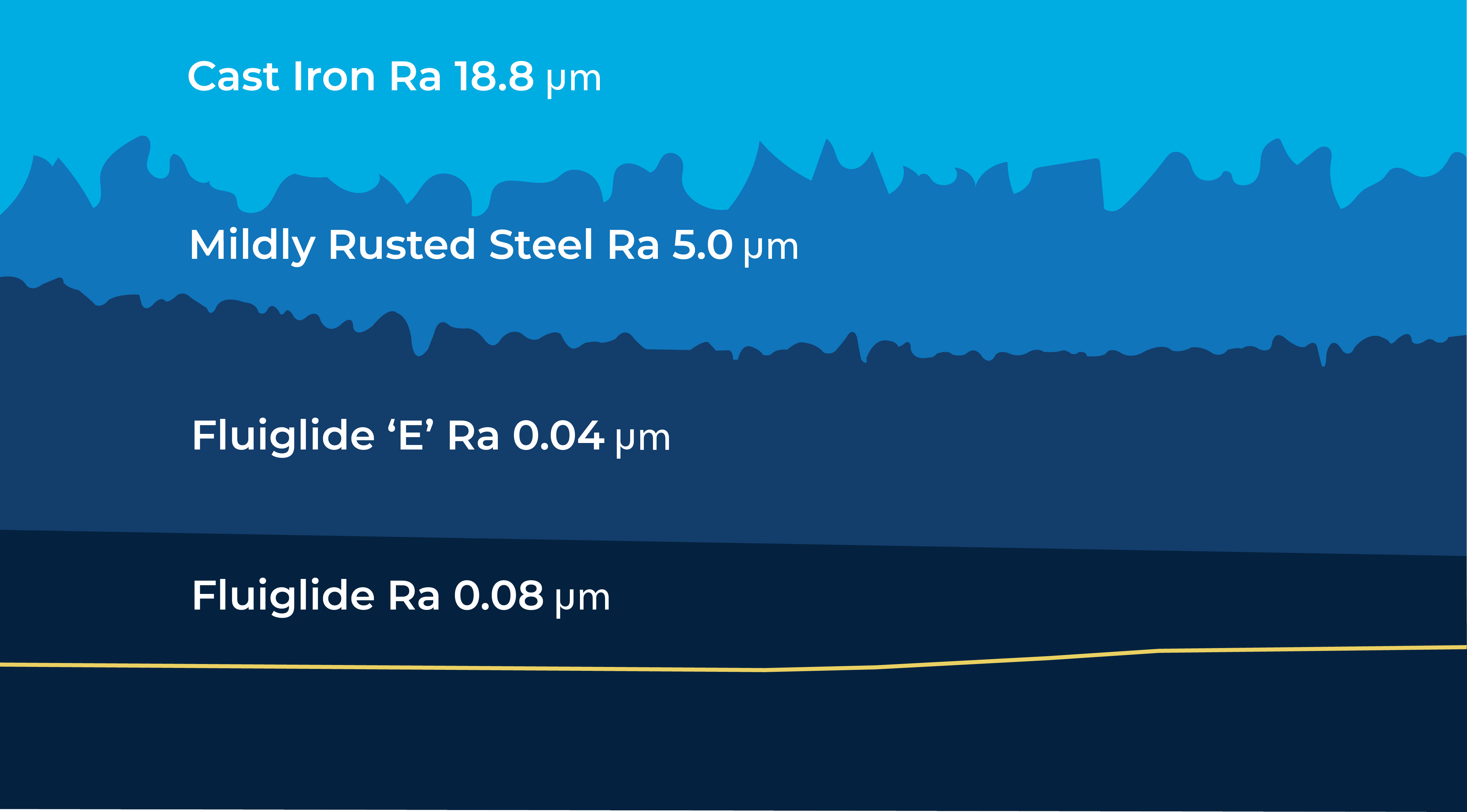

A cold cured, highly modified chemically resistant, two-pack resin system filled with stabilising enforcement to reduce cold flow characteristics. Fluiglide has good gloss with a waxy appearance and feel when cured.

Fluiglide E:

A cold cured 100% solids epoxide, specially modified to give a low roughness amplitude with poor wet out properties.

The purpose of the materials is to reduce fluid friction and increase the flow rate in the boundary layer, thereby reducing the power requirements and increasing the equipment efficiency of hydraulic parts in pumps. This applies both to reducing fluid transmission losses through pipes and channels and to increasing the efficiency of fluid propulsion systems.

By investing in Kirloskar Corrocoat solutions one can get

-

Superior surface finish to hydraulic passages in less time and efforts.

-

Superior surface finish helps in boundary layer suppression which ultimately results in higher effective Hydraulic passages.

-

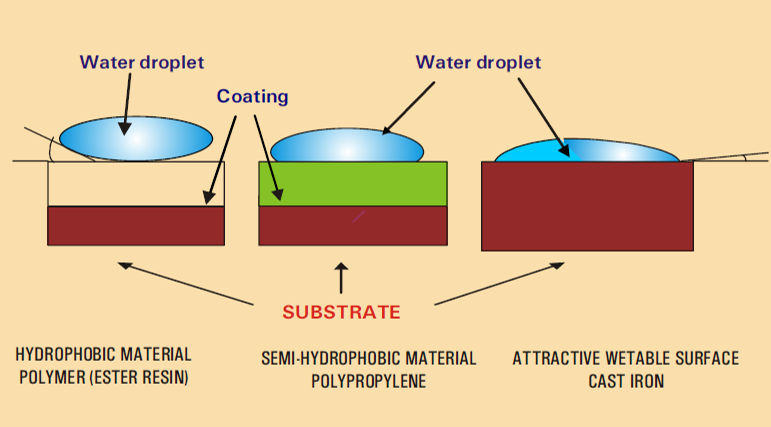

Coating is Hydrophobic in nature & nullifies the Intramolecular force of attraction between Fluid & base substrate.

-

Combination of Superior surface finish and Hydrophobic nature results in remarkable reduction in the frictional losses.

In-house Pump Testing Facility:

At Kirloskar Corrocoat we know that our coated Pumps will be used in critical applications and wherever necessary, Pumps can be tested in accordance with BS 5316 Class C and Class B; API 610; IS 9137 or customer standard in the Testing lab which is largest in Asia and certified by BHRA.

“Energy Saved is Energy Produced” - along with combating the corrosion important is to be efficient in one or other way, here with our coatings you can be assured of having efficient pumping system along with preserving the same system for longer time.

Let's calculate your potential savings and develop a custom efficiency improvement plan.

© 2023 KIRLOSKAR CORROCOAT PRIVATE LIMITED. ALL RIGHTS RESERVED | CIN NO. U28920PN2006PTC022240