In industries such as Oil & Gas, power, sugar, water treatment plants etc., storage tanks are vital assets that ensure uninterrupted operations. However, their constant exposure to aggressive chemicals, water, and harsh external conditions makes them highly vulnerable to corrosion throughout their entire structure.

While tank bottoms are well known for being prone to under-storage corrosion, the shells, roofs, and external surfaces also face serious risks if not properly protected. Neglecting these areas can result in leaks, contamination, unexpected shutdowns, and soaring repair costs. A smart preventive strategy involves applying whole tank coating systems—and high-performance coating solutions like glass flake coatings have emerged as the gold standard in corrosion protection.

Corrosion Risks Across Tank Sections:

Each section of a storage tank experiences unique challenges:

♦ Tank Bottoms:

-

Constant contact with stored liquids leads to chemical and water-induced corrosion

-

Trapped oxygen/moisture between the bottom and foundation causes underfloor pitting

-

High pressure from stored contents accelerates wear

♦ Tank Shells:

- Continuous contact with fluids at varying levels creates differential corrosion zones

- Vapors and gases attack the upper sections, while immersion areas face chemical stress

♦ Tank Roofs:

- Exposure to condensation, vapors, and external weather conditions leads to corrosion from both inside and outside

- In floating roof tanks, rim seal areas are particularly vulnerable to aggressive attack

♦ External Surfaces & Annular Plates:

- Soil-side and weather-side exposure introduces corrosion due to ground moisture, rainfall, and temperature variations

- Microbial attacks in damp soil further accelerate degradation

Failure to protect all these areas results not only in structural damage but also in safety hazards, environmental risks, and costly operational downtime.

Why Glass flake Coating on Tanks Internal & External is a Must ?

Glass flake Coating acts as the first line of defense against corrosion by isolating the base metal from aggressive environments. For critical assets like storage tanks, coating is not just maintenance—it’s an essential asset protection strategy.

Benefits of comprehensive whole-tank coating include:

- Preventing contamination of stored products

- Protecting against leakage and soil/water pollution

- Maintaining tank strength and safety compliance

- Reducing lifecycle maintenance costs and unplanned shutdowns

Understanding Glass Flake Coating Technology:

Glass flake coatings are designed for harsh industrial applications where ordinary paints, rubber lining or FRP linings often fail. The technology embeds ultra-thin glass flakes into a resin matrix like brick structure, forming a dense, laminated shield creating a torturous path to corrosion ions. This barrier significantly reduces permeability to water, oxygen, and chemicals, making it a highly reliable anti-corrosion safeguard.

Key Advantages:

-

Exceptional Barrier Strength:

The KCPL make glass flake structure creates a complex “tortuous path” that significantly slows corrosive agents from reaching the metal surface, providing superior protection compared to conventional coatings.

-

Superior Chemical Resistance:

Glass flakes embedded in the resin make the coating highly resistant to aggressive chemicals, hydrocarbons, and process fluids commonly found in industrial tank environments.

-

Durability Under Stress:

This coating offers excellent resistance to abrasion, erosion helping tanks withstand harsh operational conditions.

-

Low Maintenance:

By reducing permeability and degradation, glass flake coatings extend inspection intervals and lower overall maintenance costs.

-

Standards Compliance:

These coatings meet industry standards such as NACE, ASTM etc., ensuring reliable, long-lasting corrosion protection for critical assets.

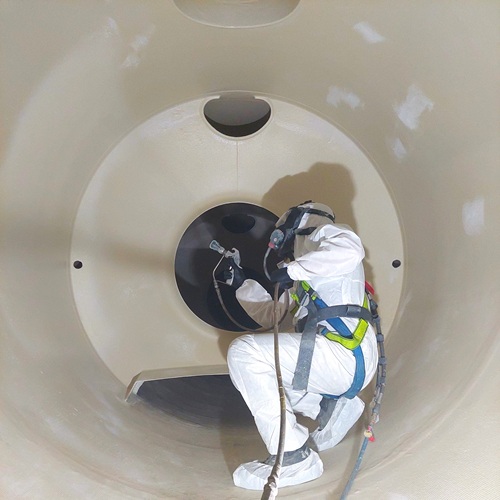

Internal and External Glass flake Coating of Tanks:

-

Internal Coating:

Protects against corrosion from stored liquids, vapors, and condensates—applied to floors, shells, and roofs using Polyglass series products. It often used with matting systems for enhanced durability.

-

External Coating:

Shields against soil-side corrosion, groundwater damage, rain, and microbial attack with Plasmet series products.

This makes glass flake coatings ideal for entire tank systems, ensuring they stay structurally sound and contamination-free.

Conclusion:

Tank coating is not optional — it is a must for ensuring long-term protection, safety, and performance. Partial protection leaves critical surfaces vulnerable to corrosion, chemical attack, and costly failures. Kirloskar Corrocoat’s high-performance glass flake technology makes whole-tank protection possible, delivering:

- Proven resistance to aggressive chemical and moisture attack

- Extended tank service life and reliability

- Environmental and safety compliance

- Reduced total cost of ownership

By making tank Glass flake coating by Kirloskar Corrocoat a priority today, industries secure reliability and avoid tomorrow’s unplanned shutdowns and repair costs.

“Because in the end, it’s not just what’s inside your tank that matters—it’s how well you protect the entire tank.”