In thermal power plants, Cooling Water (CW) pumps are the heart of the system, pumping massive water volumes. They are also, without question, the largest auxiliary power consumers. For plant managers, the initial purchase price of this equipment is a known capital expense. However, it represents a fraction of the true lifetime cost.

For a pump with a 20-year lifespan, the initial purchase price accounts for only 2.5-3% of the total cost of ownership. Maintenance adds another 2-2.5% The remaining 95% is consumed entirely by energy cost of pump over 20 years.

This 95% is where plant profitability is won or lost. Unfortunately, from the moment a new CW pump is commissioned, that cost is engineered to rise. The culprit is internal surface degradation—a problem Kirloskar Corrocoat (KCPL) treats not just as a maintenance issue, but as a critical energy management challenge.

The Mechanism of Efficiency Loss in CW Systems:

The operational environment of a CW system—handling river water, seawater, or treated water with high chlorides and suspended solids—is a perfect storm for corrosion.

This degradation follows a predictable and costly path:

- Initial Corrosion: The bare metal surfaces of the pump's hydraulic passages begin to corrode.

- Nodular Growth: This corrosion is rarely uniform. It manifests as pitting and the formation of tubercles, or "nodular growth"4. This creates a rough, uneven internal surface.

- Increased Friction: The increased surface roughness results in significant friction drag within the liquid's boundary layer (the water directly touching the pump casing).

- Power Drain: To move the same volume of water against this higher friction, the pump must work harder, drawing more power.

This gradual, often-unseen performance drop-off is a silent, compounding drain on the plant's operational budget.

The KCPL Solution: Fluiglide Coatings for Energy Recovery

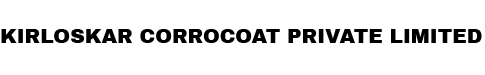

While KCPL is a leader in heavy-duty, glass-flake anti-corrosion coatings, the unique challenge of pump efficiency demanded a specialized technology. This led to the Fluiglide coating system. First introduced in 1985, Fluiglide has now been applied to lakhs of pumps worldwide. It was engineered specifically to solve the dual problem of corrosion and energy loss.

It is not just a protective barrier; it is an engineered technology for hydraulic performance enhancement. The system, which includes Fluiglide and Fluiglide E, works by fundamentally altering the physics at the pump's surface.

How Fluiglide Coating Delivers Measurable Energy Savings?

The Fluiglide coating system achieves its results through a specific, engineered combination of properties that conventional coatings cannot match.

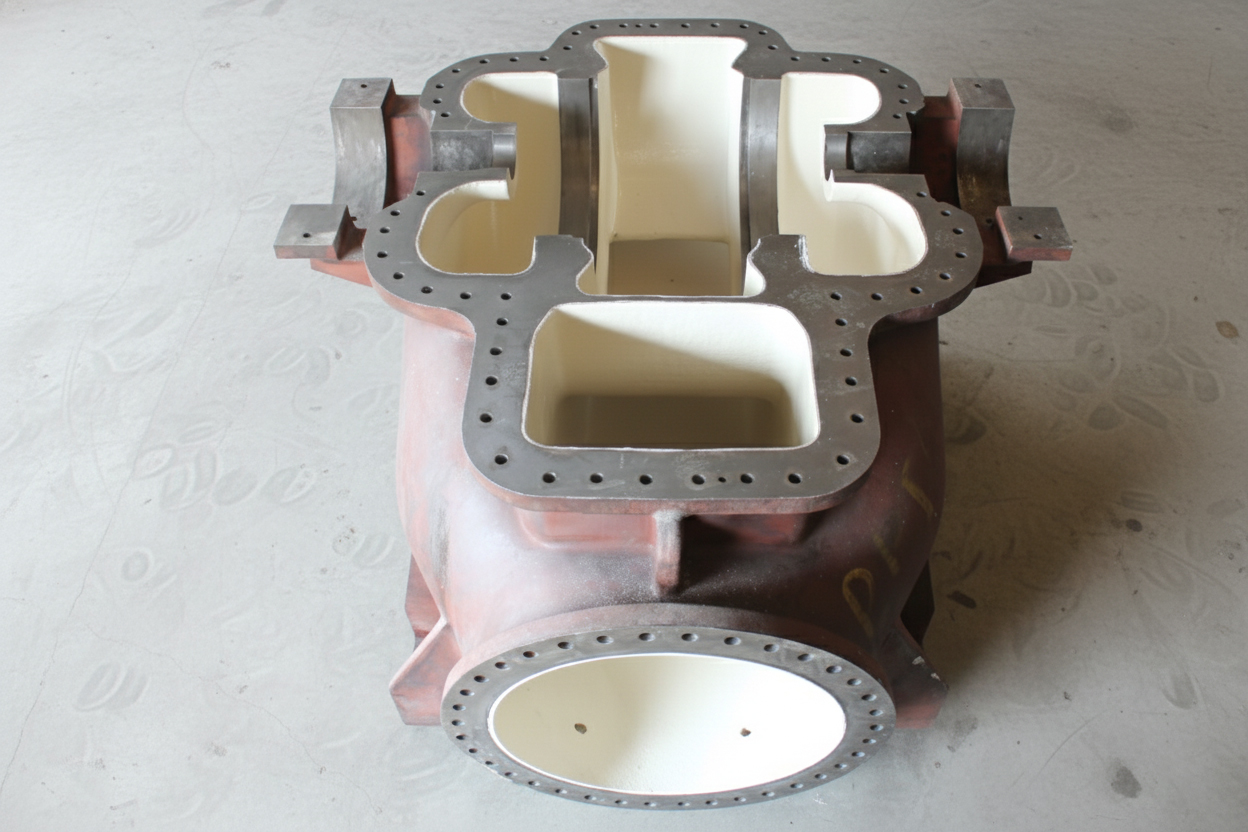

1. Creates a Superior, Low-Roughness Surface:

Fluiglide coatings are specially modified to provide a "low roughness amplitude". This creates an ultra-smooth surface finish that is far superior to the original cast metal and dramatically smoother than a corroded, pockmarked surface.

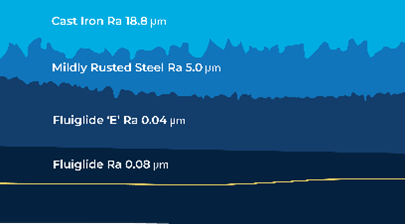

2. Delivers a Hydrophobic Surface:

The cured coating is hydrophobic (water-repelling) by nature. This property "nullifies the Intramolecular force of attraction between Fluid & base substrate".

3. Achieves Boundary Layer Suppression:

The combination of an ultra-smooth surface and hydrophobic properties results in "boundary layer suppression". In simple terms, the water does not "stick" to the casing. It flows over the surface with minimal drag, leading to a remarkable reduction in frictional losses.

This reduction in friction directly translates to less power required from the motor to achieve the same flow rate, thereby increasing the pump's overall efficiency.

The Financial Impact: Converting a Cost to an Investment:

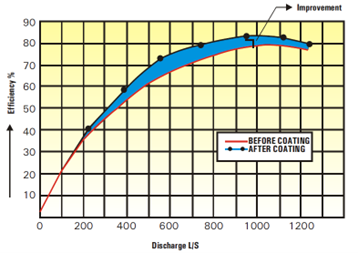

These are not hypothetical gains. The performance of the Fluiglide system has been extensively tested and validated at the Kirloskarvadi workshop, which houses Asia's Largest Pump Testing Facility. This facility, certified by BHRA, allows for testing to rigorous standards.

-

For Old/Refurbished CW Pumps:

In old, used pumps, our coating and refurbishment services can improve efficiency by more than 4%, depending on the pump's condition and specific speed. In some cases KCPL has achieved more than 15% efficiency improvements.

-

For New CW Pumps:

Applying Fluiglide to new pumps can improve the design efficiency by 1% to 2%. This not only provides an immediate energy saving but also prevents the efficiency degradation that normally begins on day one.

The payback on this investment makes it a compelling business decision. With an average 4-5% efficiency improvement, the Return on Investment (ROI) based on energy savings alone is typically less than six months.

The system delivers a dual benefit that is at the heart of the KCPL philosophy. It provides an effective corrosion barrier, preventing fall-off in performance and extending asset life, while simultaneously reclaiming significant energy.

For a power plant where "Energy Saved is Energy Produced", addressing the 95% energy cost of CW pumps is the most logical and impactful reliability decision you can make.