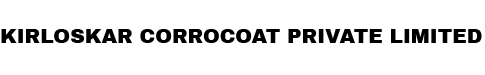

Condenser water boxes and tube sheets are the critical interface in a plant's cooling system, whether in a thermal power station, a petrochemical complex, or any other industry. These components are tasked with managing high volumes of cooling water to facilitate essential heat exchange.

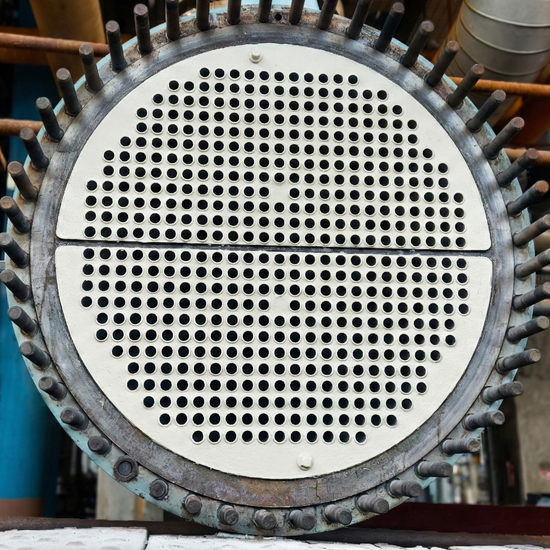

However, no other piece of equipment faces such a complex and aggressive combination of corrosion mechanisms. Failure here is not a minor leak; it's a catastrophic breach that can contaminate processes, force an emergency shutdown, and result in millions in lost production and repair costs.

At KCPL, we approach this challenge through first-principles engineering. Durable protection begins with understanding why failure occurs—not merely treating its symptoms.

The Engineering Challenge: What Happens Inside a Water Box & tube sheet?

Water boxes are typically fabricated from carbon steel or cast iron. They connect to tube sheets (often Copper-Nickel, Titanium, or Stainless Steel) and tubes. This setup creates a perfect storm for corrosion:

The corrosion found in water boxes is rarely a single, simple mechanism. It is a synergistic attack where multiple forms of corrosion work together to destroy the asset.

Dominant Corrosion Mechanisms in Condenser Water Boxes

- Galvanic Corrosion: The water box acts as the anode in a massive galvanic cell formed with the more noble tube sheet and tubes. Without a perfect dielectric barrier, the carbon steel sacrifices itself, leading to rapid wall thinning.

- Erosion-Corrosion: High-velocity water creates turbulence, especially at the inlet and reversal points. This physical force strips away passive oxide layers. This fresh, un-passivated steel is then exposed to the electrolyte, corroding rapidly, only to be scoured away again in a vicious cycle of metal loss.

- Permeation: Conventional epoxy, coal tar epoxy, PU, and similar “normal” coatings are semi-permeable. In high-pressure CW systems, water molecules and dissolved oxygen slowly diffuse through the coating film. Over time this causes: Osmotic blistering, Under-film corrosion, Loss of adhesion, Premature coating failure. Even when visually intact, the coating may already be corroding underneath.

- The Flaw in Traditional Rubber Lining: Historically, rubber lining was the go-to solution. However, rubber is prone to aging, debonding (peeling) due to vacuum conditions in the condenser, and damage from debris. Once the rubber breaches, the corrosion is often localized and catastrophic.

- Pitting and Crevice Corrosion: In low-flow or "dead" zones, deposits can settle on the steel surface. Underneath these deposits, a highly localized and aggressive corrosion cell forms, leading to deep "pits" that can perforate the water box wall. Similarly, the small gaps at flanges and fasteners (crevices) create differential aeration cells that drive rapid, localized corrosion.

The KCPL Solution: Glass Flake Technology

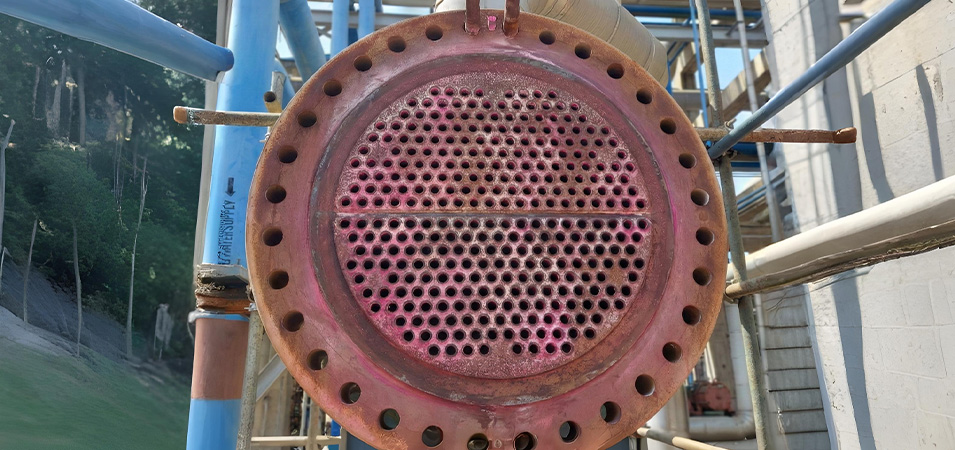

To combat these aggressive environments, KCPL utilizes High-Performance Glass Flake Coatings—specifically our Corroglass and Polyglass series.

Unlike standard coatings, these systems are heavily loaded with micron-sized glass flakes. These flakes align parallel to the substrate, creating a complex brick-like structure, multi-layered "tortuous path" for any corrosive ions attempting to reach the steel surface.

Why Glass Flake is Superior for Water Boxes & tube sheets:

- Extremely Low Permeability: The glass flakes create a nearly impermeable barrier, significantly reducing water vapor transmission rates. This prevents the blistering often seen in standard epoxy systems.

- Dimensional Stability: The coefficient of thermal expansion of our glass flake composites closely matches that of carbon steel. This ensures the coating does not crack or delaminate during the thermal cycling inherent in condenser operations.

- Galvanic Isolation: Our coatings act as a complete dielectric barrier, electrically isolating the water box from the tube sheet and stopping the galvanic reaction at the source.

- Extended Asset Life: This system moves the asset from a reactive maintenance cycle (repairing every 1-2 years) to a proactive one, providing proven, maintenance-free protection for 10-15 years or more.

- Seamless, Monolithic Protection: Unlike rubber linings, glass flake coatings are spray- or hand-applied, conforming perfectly to complex geometries and eliminating seams, joints, or overlaps.

Validated in the Power Sector

KCPL has successfully treated water boxes for major power generation utilities, effectively handling cooling media ranging from raw river water to chemically aggressive seawater. Our solutions are designed to protect critical CW system components including pumps, valves, and heat exchanger tube faces.

Conclusion:

Corrosion in condenser water boxes and tube sheets is a multi-mechanism engineering problem that cannot be solved with traditional, single-layer protection systems.

High-performance glass flake coatings provide a holistic, long-term solution, addressing permeability, galvanic interaction, erosion, and localized corrosion—simultaneously.

“By extending asset life, reducing unplanned shutdowns, and lowering lifecycle costs, these systems reflect the core KCPL philosophy: Salvage, Stimulate, Sustain”