Pipelines are the lifelines of various industries, transporting essential resources across vast distances. From oil and gas to water and chemicals, these vital arteries ensure the smooth operation of our modern world. However, the constant flow of fluids and exposure to harsh environments can take their toll on pipelines. Corrosion, abrasion, and erosion are major threats that can lead to costly repairs, downtime, and even safety hazards.

With decades of experience protecting hundreds of kilometres of pipelines each year, Kirloskar Corrocoat Private Limited, along with technology partner Corrocoat Ltd., has developed specialized coating techniques for pipeline internal coating starting from pipe diameters of 3 inches and onwards and external surfaces with no limitation. Kirloskar Corrocoat Private Limited (KCPL) offers effective solution with polyester, epoxy and vinyl ester glass flake coating for pipeline internal & external coating, even in the most challenging environments, ensuring their longevity and optimal performance.

Kirloskar Corrocoat has developed pipeline internal coatings that can withstand service conditions in sea water, DM water, raw water, and many other corrosive fluids. Expceted Life of our pipeline coatings in sea water service environment is more than 30 years.

What is Glass Flake Coating?

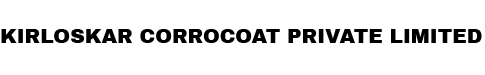

Glass flake coating is a high-performance coating system that utilizes specially crafted glass flakes embedded in a resin matrix. Imagine a maze of overlapping glass flakes, this is the structure of glass flake coating, a technology that shields pipelines from the ravages of time and environment. By forcing moisture and other detrimental substances to take a tortuous path, the coating drastically slows down their permeation, ensuring the long-term health and performance of these vital arteries.

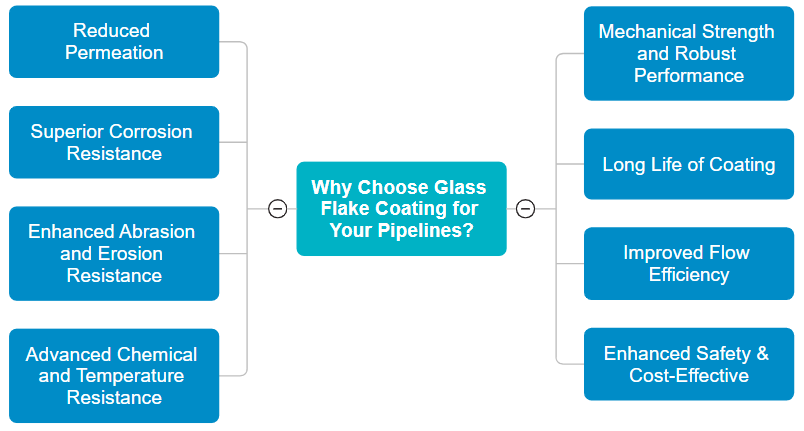

Why Choose Glass Flake Coating for Your Pipelines?

-

Reduced Permeation:

The glass flakes act as a barrier, minimizing the penetration of moisture vapor through the coating, further enhancing corrosion resistance.

-

Superior Corrosion Resistance:

Glass flake coatings offer exceptional resistance to a wide range of chemicals, including acids, alkalis, and solvents, protecting pipelines from the corrosive effects of transported fluids and harsh environments.

-

Enhanced Abrasion and Erosion Resistance:

The overlapping flakes create a smooth, low-friction surface that resists wear and tear from the transported fluids, especially beneficial for pipelines carrying abrasive materials like slurries and sand.

-

Advanced Chemical and Temperature Resistance:

KCPL make Glass Flake Coatings Withstand temperatures up to 150°C (immersed) and 260°C (non-immersed), offering exceptional protection in harsh environments.

-

Mechanical Strength and Robust Performance:

Glass flake Coating ensure long-lasting durability and optimal performance under demanding conditions. Also, it requires minimal maintenance, saving valuable time and resources.

-

Long Life of Coating:

Compared to conventional coating systems, our glass flake coatings offer significantly longer life, reducing maintenance costs and downtime. As per our experience, the expected service life of Pipeline internal coating in sea water condition can be more than 30 years.

-

Improved Flow Efficiency:

The smooth surface reduces friction, leading to improved flow rates and reduced energy consumption.

-

Enhanced Safety:

Pipeline internal coating and Pipeline external coating gives protection from corrosion and other damage, glass flake coatings contribute to a safer working environment.

-

Cost-Effective:

Although the initial cost of glass flake coating may be higher than conventional coatings, the long-term benefits in terms of reduced maintenance and extended lifespan significantly outweigh the initial investment.

Conclusion:

Pipeline Internal Coating is scientific art to be performed with expert Technology and Technical Know How, this innovative solution can help you save money, improve efficiency, and ensure the safety and reliability of your pipeline system. Invest in the advanced protection of Kirloskar Corrocoat's internal glass flake coating solutions. Do not let corrosion and other threats compromise the integrity and performance of your pipelines.

Contact Kirloskar Corrocoat today to discuss your specific needs and explore how their coatings can help you achieve optimal pipeline performance and longevity.